Coal and Energy Resource Directions

Updated Monday June 18, 2012The power generation industries in China, India and the U.S. are transforming coal so it may be used more efficiently. This lowers the cost of generating electricity. One coincidental benefit is that cleaner energy is produced. Other benefits are the flexibility to substitute alternate energy sources for coal and to eventually move to hydrogen fuel production without needing to replace gas-fired power stations.

|

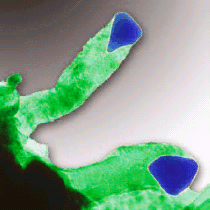

| From coal to clean energy (Topsoe) Whisker carbon formed on nickel crystal |

This is technology being deployed widely in China. India is keen to follow China's example. U.S. plans to increase use of this technology have been temporarily put on hold with the serendipitous windfall of abundant cheap natural gas.

The Australian coal industry itself may share the same misunderstanding as Tony Abbott. It is seemingly pursuing a strategy to construct as many new coal-fired power stations as possible. The effect of this strategy is to lock-in continuing demand for coal before the mistakenly suspected "phasing-out" of coal can begin.

The U.S. coal industry seems to share similar mistaken views as Tony Abbott and the Australian coal industry. For example, the U.S. Institute for Energy Research president Jim Pyle expresses concerns such as:

- "Question for Mr. Kushner: Who decides what energy sources make the most sense and why do we need Washington to force transition?"

- "The public has made the clear connection that making affordable energy more expensive is crippling the economy and will respond."

- "Transition from coal? What about the rest of the world? And do you also oppose exporting coal, Mr. Waxman?"

You can follow the discussion of policy reform in the U.S. energy industry on Twitter: hashtag "#NJClearair".

China Adopting More Efficient (and Cleaner) Coal Technology

|

| From coal to clean energy - Topsoe |

China has built 50 coal gasification plants in the last 10 years and has another 40 in planning or under construction. On 21 May 2012 the article "China to Invest in Coal Gasification - with GEs help" by John Daly reported:

With more than 50 licensed facilities in China, GE’s gasification technology is one of the most widely deployed in the industry, while Shenhua is one of the world’s largest coal and energy companies, with integrated coal production, power generation, railway, port and shipping infrastructure.

...

Putting the final seal of approval on the project GE Energy Thermal Products president and CEO Paul Browning concluded, “Coal plays an important role in the economies of both the U.S. and China, and gasification technology allows us to use this abundant and low-cost resource in a much cleaner way.

...

The emphasis shift in coal power generation from thermal plants to utilizing IGCC technology is a key element in the Chinese leadership’s efforts to maintain its economic momentum by providing its vast industrial base uninterrupted power supplies.

New technology is increasing efficiency of converting coal to gas. China is building commercial-scale plants as new technology becomes available. For example:

- "Rocketdyne coal gasification provides an alternative fuel source", February 2012.

- "Topsoe new Coal to SNG plant for the Yinan Substitute Natural Gas (SNG) Project", March 2012.

India to Follow China's Lead with More Efficient (and Cleaner) Coal Technology

On 29 May 2012 the Economic Times reported in the article "India needs to master the coal-gasification technology":

India needs to master the coal-gasification technology so as to boost both energy efficiency and attendant security.The likely impact on Australia's coal export industry can be seen from an earlier article on 12 March 2012. Reuters reported in its article "India's coal-to-gas dream takes baby steps":

...

...Integrated coal-gasification combined-cycle (IGCC) power plants, which incorporate both gas and steam turbines, vastly improve the conversion of coal energy into usable electricity.

...

Note that while the efficiency rate is just about 30% in standard coal-fired stations and 40-odd per cent using super-critical technology, the mavens hold that, in future gasification plants, the ratio could touch 70-80%. We clearly need to adopt IGCC in a big way.

NEW DELHI, March 12(Reuters) - India is at least a decade behind China in embracing technology that could convert its coal reserves into enough gas and oil to surmount chronic power shortages and halve its energy import bill of $110 billion a year.

Cheap Natural Gas in the U.S. replacing Coal-Fired Power Generation

In the U.S. plans for the construction of a number of coal gasification plants have recently been put on hold. The reason: a massive over-supply of natural gas in the U.S. has dramatically lowered the price and the continued use of coal is for the time-being at least, not competitive.

On 13 March 2012 the article "Coal’s Share of U.S. Electricity Generation Falls to 35-Year Low" by Moran Zhang reported:

The share of U.S. power generation that comes from coal has fallen to near a 35-year low, as electric power plants shift to cheaper natural gas.

Although coal is still the main fuel for electricity generation, its share of monthly power generation in the U.S. dropped below 40 percent in the last two months in 2011, according to the Energy Department. The last time coal's share of total generation was below 40 percent for a monthly total was March 1978.

...

"Natural gas combined-cycle units operate at higher efficiency than do older, coal-fired units, which increases the competitiveness of natural gas relative to coal," the Energy Department said in a statement.

Natural gas prices have continued their downward trend this winter as a result of warmer-than-normal temperatures, ample natural gas in storage and growing natural gas production, which has been boosted by companies tapping so-called shale reservoirs using a technique called hydraulic fracturing, also known as "fracking."

United Kingdom's Variation on More Efficient (and Cleaner) Coal Technology

Updated Friday August 17, 2012Stage 1 of the coal gasification technology China is deploying converts coal into synthesis gas. Further stages then convert this to methane ("Substitute Natural Gas" or SNG) and carbon dioxide.

In a variation that eliminates the cost of coal mining and does away with the plant for the initial stage that converts coal to synthesis gas, the United Kingdom is developing Underground Coal Gasification projects.

These projects convert deep coal seams that cannot be commercially mined into synthesis gas which is then piped to the surface for further processing stages as in China's coal gasification plants.

Australian Coal industry seeks 15-year policy reform delay

Why is Australia to spend over $1 billion on CarbonNet and take 15 years developing new Carbon Capture technology ----

---- when proven technology has existed for decades in the USA?

A Possible Reason for the Coal Industry to Delay Pre-Combustion Carbon Capture

Post-combustion Carbon Capture and Storage (CCS) provides a justification to continue

construction of coal-fired power stations. It holds out a promise of one

day being able to reduce emissions of such power plants.

Once a coal-fired power plant is constructed, the coal industry is guaranteed a customer for at least 40 years.

Gasification of coal with pre-combustion Carbon Capture eliminates the reason for constructing any new coal-fired power stations. Once converted to gas, the fuel can be used in high-efficiency combined-cycle gas turbine (CCGT) power stations. In addition a number of toxic components of coal such as mercury can be economically removed when the coal has been converted to gas.

The demand for coal would go down when natural gas prices fall. There would be no guaranteed demand to provide fuel for new coal-fired power stations.

A gas-fired power station achieves 60 percent thermal efficiency, much higher than the 40 percent for advanced coal-fired power stations. This difference also results in lower demand for coal.

Source: Carbon Capture and Storage - Questions and Answers, 14 November 2011, Department of Primary Industry, Victoria -

Once a coal-fired power plant is constructed, the coal industry is guaranteed a customer for at least 40 years.

Gasification of coal with pre-combustion Carbon Capture eliminates the reason for constructing any new coal-fired power stations. Once converted to gas, the fuel can be used in high-efficiency combined-cycle gas turbine (CCGT) power stations. In addition a number of toxic components of coal such as mercury can be economically removed when the coal has been converted to gas.

The demand for coal would go down when natural gas prices fall. There would be no guaranteed demand to provide fuel for new coal-fired power stations.

A gas-fired power station achieves 60 percent thermal efficiency, much higher than the 40 percent for advanced coal-fired power stations. This difference also results in lower demand for coal.

What's Happening?

Source: Travel Outcomes Report, Japan, September 2011, Department of Primary Industry, Victoria -Since 2009, many Japanese delegations have visited Victoria to discuss low emission coal technologies, carbon capture and storage (CCS), and the use of Victorian brown coal resources.Source: CO2CRC Research Symposium 2011, 30 November 2011 -

These visits have reinforced Japan’s interest in Victorian brown coal and collaboration with Victoria on project development and R&D, to develop low emission coal technologies such as gasification, CCS, the production of synthetic natural gas (SNG), and liquid fuels.

The Commonwealth is also collaborating with the Victorian Government to evaluate proposals by Japanese companies to apply gasification technologies to brown coal.

The idea is to convert Victoria's abundant supply of brown coal to higher value commodities such as substitute natural gas, hydrogen and liquid fuels whilst capturing the CO2.

Source: Carbon Capture and Storage - Questions and Answers, 14 November 2011, Department of Primary Industry, Victoria -

Investing in this technology will also enable the development of other uses for coal such as production of other carbon sourced products such as diesel or hydrogen, which potentially could be used as a low emissions fuel for cars, synthetic natural gas, fertilisers and methanol.

Tony Abbott Addresses the Minerals Council of Australia

In an Address to the Minerals Council of Australia at Canberra on 30 May 2012, coincidentally just one day after the above article on India's need to follow the example set by China to embrace more efficient energy-from-coal technology, Tony Abbott said:...We all know what the carbon tax is designed to do: it is designed to reduce our use of coal and our use of gas [sic]. In other words, it is designed to limit the production, ultimately, of the minerals upon which our country so critically depends [sic]...The government’s own documents say that Australia’s energy production from coal, absent carbon capture and storage, will fall from over 70 percent right now to 10 percent by 2050.

So, the carbon tax is designed to damage the very things on which our country's wealth depends [sic]. The only way our country's wealth can survive the carbon tax is if other countries don't do what we're doing. If China and India took the same attitude to coal and gas that we are taking, our export industries would be in diabolical trouble...

0 comments:

Post a Comment