Existing coal-fired power stations using low-grade coal might continue to generate particulate and sulphur dioxide emissions until they are decommissioned. Some are fitted with scrubbers and other post-combustion filters to reduce these emissions. This approach reduces the efficiency of already inefficient coal-fired power stations:

The heating value of Indian coal is, on average, about 60 percent of the heating value of coal burned in the United States. This increases the amount of coal that must be burned to generate a given heat input, implying higher auxiliary electricity consumption to run coal grinding equipment, conveyors, and pumps.

Auxiliary generation... will also increase if electricity is used to run pollution abatement equipment, such as electrostatic precipitators ( ESPs ) and flue-gas desulfurization units ( scrubbers ) . We note although coal-fired power plants in both countries have ESPs, only three plants in India currently have scrubbers.1

In the meantime there are options to increase efficiency and reduce harmful emissions until it is feasible to decommission these coal-fired power stations.

One of these options is to pre-process the low-grade coal before combustion. The technology available to do this has several advantages. It eliminates the particulate and sulphur dioxide emissions and, more importantly, increases the efficiency of these coal-fired power stations. Scrubbers and other post-combustion filters are no longer needed.

Low-grade coal contains relatively high levels of contaminants and moisture content. The moisture content reduces the energy available for power generation when its burned because energy is wasted converting the moisture into water vapour. The contaminants increase the energy that is used to run pollution abatement equipment.

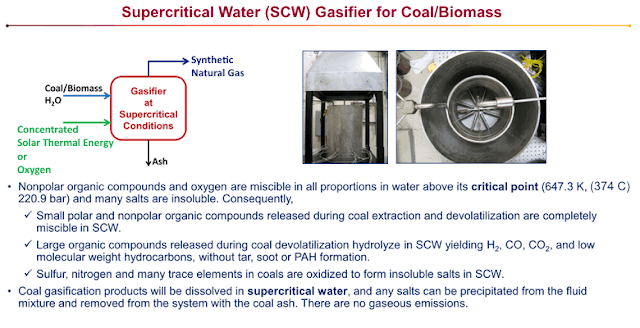

To understand the available technology this simplified model gives a reasonable approximation of what takes place; Consider a process in which carbon and water are placed in a reaction vessel and an environment is created to promote a desired reaction that uses little or no external energy. The reaction breaks down some of the water into oxygen and hydrogen. The oxygen reacts with half of the carbon to form carbon dioxide and the hydrogen reacts with the remainder of the carbon to create methane. The energy released by the reactions with carbon provide the energy needed to break down water into oxygen and hydrogen.

The methane can be separated to use in place of low-grade coal in the existing coal-fired power stations. There are no particulates or sulphur dioxide to be removed from the exhaust gases. When methane burns, about half the energy is produced by the reaction of carbon with oxygen to produce carbon dioxide, and about half is produced by the reaction of hydrogen with oxygen to form water vapour. Note that the total amount of energy is the same as would have been produced if all of the carbon had been burned and not pre-processed into carbon dioxide and methane. The moisture content that was present in the low-grade coal has been separated, as water, before combustion. No energy is wasted converting that moisture into water vapour.

Research on this technology was conducted in several countries interested in producing methane from biomass that contains significant amounts of water. That research has advanced into at least three commercially available products. These can be adapted to carry out the desired pre-processing of low-grade coal into methane:

|

| Upgrading low-grade coal to methane |

1

Chan, Hei Sing (Ron), Maureen L. Cropper, and Kabir Malik.

2014. "Why Are Power Plants in India Less Efficient Than Power Plants in the United States?" American Economic Review, 104(5): 586-90.

DOI: 10.1257/aer.104.5.586