Arizona State University Research Partnership With Cutting Edge 24/7

Solar Technology

Arizona State

University and AORA Solar NA announce a collaboration that will begin the

development of a hybrid concentrated solar system on the Tempe campus that employs

a Solar Tulip to concentrate the sun's energy, turning it into electricity.

Tempe, AZ - March 13, 2014

Solar generated electricity, which can suffer from intermittency

issues and related impacts on the grid, is about to blossom at Arizona State University.

Work will now begin on the development of a hybrid concentrated solar system,

following a contract signing with ASU and AORA to provide research expertise in

order to enhance the efficiency of this unique technology.

AORA Solar NA, has agreed to

install the first ever Solar Tulip hybrid generating facility in the United

States on university land, and ASU faculty, research staff, and students will

work hand in hand with AORA to enhance the system. This project includes the

installation of a hybrid concentrated solar power plant that employs a Solar

Tulip to concentrate the sun’s energy, turning it into electricity. The system

produces power 24/7, moving seamlessly from solar to natural gas or biogas and is

also promising because it uses little to no water while producing a high

quality thermal output in addition to power.

AORA Solar NA, a U.S. company, will work with a multi-disciplinary

ASU team to research options to increase efficiency, improve reliability,

utilize the exhaust heat and decrease the cost of this Israeli developed

technology. AORA will construct the demonstration power plant, which includes a

tower (approximately 100 feet high) appropriately called the Solar Tulip, on

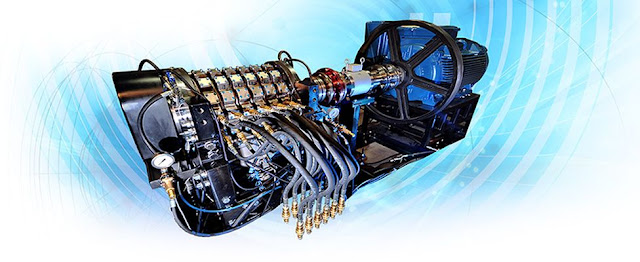

undeveloped land near the Karsten Golf Course in Tempe. The technology includes

a collection of mirrors to concentrate the sun’s rays to heat compressed air to

more than 1800 degrees Fahrenheit and drive a gas turbine. The rated output of

the Tulip system is 100 kilowatts of electricity and an additional 170

kilowatts of thermal energy, about enough energy to power between 60-80 homes.

At night, or when overcast, the Tulip can use a wide range of fuels

to heat the air and is thereby able to produce power and heat round the clock.

The system is modular in design, allowing for multiple Tulips to work together,

enabling the technology to match growing electric demand requirements. The

relatively small footprint makes this system a potentially perfect complement

to housing developments, or industrial parks, and offers an option to enhance

grid stability in the presence of transient renewable generation.

“ASU is a natural partner for us, not only because of its sunny

location, but because of the university’s dedication to innovation and

sustainability,” said Zev Rosenzweig, CEO of AORA Solar. “We are excited to

make our debut here in the United States with this innovative technology where

we will continue to grow and develop the Tulip into a system that cities and

industries around the world use to generate continuous energy with renewable

resources. ASU’s breadth of research capability will undoubtedly allow us to

increase output, and reduce overall costs which will bring us to commercial

viability. Our confidence in this project is enhanced with the participation of

Project Director, Ellen Stechel, who has spearheaded the concept from the

beginning, along with her colleagues Gary Dirks, William Brandt and the ASU

LightWorks team.”

AORA Solar is currently operating two additional research

facilities, one located in a solar research park in Almeria, Spain, and the

original unit in Israel. These systems can be controlled remotely via computer,

a unique capability that provides innovative options for possibilities in the

U.S. and indeed around the world, including developing countries.

The ASU/AORA collaborative relationship will not only bring ASU

closer to its goal of becoming carbon neutral by 2025, but it will also benefit

students and researchers across multiple fields of study.

“This is another instance in which ASU has brought in cutting edge

technology that its students can learn from and help perfect,” said Sethuraman

"Panch" Panchanathan, senior vice president of Office of Knowledge

Enterprise Development at ASU. “With this collaboration, the university has

established a commitment to integrate students, faculty, and staff into

research on the Solar Tulip design to bring 24-hour solar/renewable technology

to commercialization.”

“The AORA/ASU collaboration provides a multitude of possibilities

looking forward,” said Gary Dirks, director of ASU LightWorks. “It is a perfect

example of industry and academia coming together and leveraging their unique

strengths to create collaborative projects that propel new and viable technology

into our energy future. The Solar Tulip has enormous potential both at ASU and

beyond.”

AORA Solar has contracted with GreenFuel Technologies, a

Phoenix-based General Contractor specializing in environmental energy projects

to construct the research plant at the ASU campus. Groundbreaking is expected

to occur in April, with the anticipated operation date to be sometime in the

late September/early October time frame. AORA Solar and ASU look forward to

welcoming university peers along with the public to a ribbon-cutting event at

the Tulip’s completion.

“We are pleased to host the Solar Tulip at the ASU Tempe campus,”

said John Riley, sustainability operations officer at ASU. “It is a visually

iconic piece of technology, helping to illustrate the way ASU is a destination

place for state-of-the-art research and facilities.”

This collaboration was advanced by Arizona State University

LightWorks, a research initiative that unites resources and researchers across

ASU to confront global energy challenges. The LightWorks team provided the

vision of required research, identified the multiple research windows in which

AORA will participate and is intimately involved in moving the project from

concept to fruition. With a proven track record of swiftly and strategically partnering

with a diverse set of institutions, LightWorks continues to help overcome

challenges in the fields of solar power, sustainable fuels, and energy policy.

To learn more about ASU LightWorks, visit asulightworks.com.

Left to right: Gary Dirks, director of ASU

LightWorks, Zev Rosenzweig, CEO of AORA Solar and John Riley, associate vice

president of university business services and sustainability operations officer.

# # #

About AORA

AORA, a renewable energy pioneer, is a leading developer of applied ultra-high

temperature concentrating solar power (CSP) technologies. AORA’s modular solar

power generation solutions are comprised of very small modular units (100kWe /

170kW heat) that can be linked together into centrally controlled power plants,

customized to client demand. When the amount of sunlight is not sufficient, the

system can operate on almost any alternative fuel source, thereby guaranteeing

an uninterrupted power supply, 24hr/day. To learn more about AORA Solar, please

visit http://aora-solar.com/.